Brushless DC motor is composed of motor body and driver, which is a typical electromechanical integration product. Brushless motor refers to the motor without brush and commutator (or collector ring), also known as commutator motor. As early as the 19th century, when the motor was born, the practical motor produced was the brushless type, that is, the AC squirrel-cage asynchronous motor, which was widely used. However, asynchronous motor has many insurmountable defects, resulting in the slow development of motor technology. In the middle of the last century, the transistor was born, so the brushless DC motor using the transistor commutation circuit instead of the brush and commutator came into being. This new type of brushless motor is called electronic commutation DC motor, which overcomes the defects of the first generation of brushless motor.

The stator winding of the motor is mostly made of three-phase symmetrical star connection, which is very similar to three-phase asynchronous motor. The rotor of the motor is stuck with magnetized permanent magnet. In order to detect the polarity of the motor rotor, a position sensor is installed in the motor. The driver is composed of power electronic devices and integrated circuits. Its function receives the start, stop and brake signals of the motor to control the start, stop and brake of the motor, and receives the position sensor signals and positive and reverse signals to control the on-off of each power tube of the inverter bridge to generate continuous torque; Receive speed command and speed feedback signal to control and adjust speed; Provide protection and display, etc.

DC motor has fast response, large starting torque, and can provide rated torque from zero speed to rated speed, but the advantages of DC motor are also its disadvantages. Because DC motor needs to produce the performance of constant torque under rated load, the armature magnetic field and rotor magnetic field must be maintained at 90 °, which is determined by carbon brush and commutator. The carbon brush and commutator will produce sparks and toner when the motor is rotating. Therefore, in addition to causing component damage, the use occasions are also limited. The AC motor has no carbon brush and commutator, which is maintenance-free, solid and widely used. However, the performance equivalent to that of the DC motor can only be achieved by using complex control technology. Nowadays, the semiconductor develops rapidly and the switching frequency of power components is much faster, which improves the performance of drive motors. The microprocessor speed is also getting faster and faster, which can realize the control of AC motor in a rotating two-axis rectangular coordinate system, and properly control the current component of AC motor in the two axes, so as to achieve similar DC motor control and have the same performance as DC motor.

In addition, many microprocessors have built the functions needed to control the motor in the chip, and the volume is getting smaller and smaller; Such as analog to digital converter (adc), pulse width modulator (pwm), etc. Brushless DC motor is an application that electronically controls the commutation of AC motor to obtain similar characteristics of DC motor without missing DC motor mechanism.

With the continuous improvement of domestic living standards, vacuum cleaners have gradually entered the homes of ordinary people and are gradually being accepted by more people. In some countries in Europe and the United States, the probability of choosing vacuum cleaners has reached 85%. Vacuum cleaners will also become a necessary household appliance like white appliances in the near future, not just the category of "labor tools".

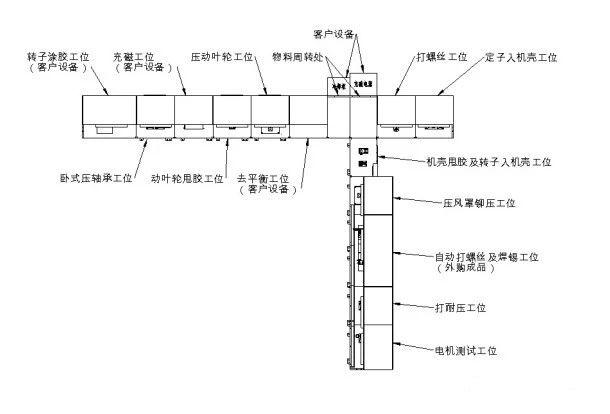

1、各工位介绍:

定子入机壳工位:将缠好线的定子压入机壳内。

打螺丝工位:手动螺丝枪将定子和机壳固定在一起。

转子涂胶工位:将转子涂胶后与铁芯粘合在一起。

卧式压轴承工位:将轴承压入转子内并保证尺寸(要求误差±0.1)。

动叶轮刷胶工位:将动叶轮与轴承配合处涂胶。

压动叶轮工位:将动叶轮压入转子内(要求误差±0.1)。

去平衡工位:将整个转子及动叶轮进行平衡处理,保证转动稳定。

物料周转处:将转子和机壳暂时存放处。

机壳甩胶及转子入机壳工位:将机壳与轴承配合处涂胶,并通过压入机壳工位将转子压入。

压风罩铆压工位:将风罩和机壳压入后并铆紧。

自动打螺丝及焊锡工位:将电路板固定在机壳上并将铁芯的铜线与电路板焊锡连接。

打耐压工位:将成品电机进行打耐压处理。

电机测试工位:将成品电机进行转动及震动测试。

2、设备主要技术参数:

装配线尺寸: 长8240mm 宽6095mm 高1800mm

设备大工作压力: 0.8MPa

设备额定工作压力: 0.4-0.6MPa

设备功率: 250W

电源电压: AC 220V